WELDING

IN CONSTANT SEARCH FOR INDUSTRIAL EXCELLENCE

This is the activity that made ACG's standing.

Considered as experts, we master the different welding technologies.

We are able to realise the means that integrate these processes.

Discover some examples below:

ACG PRODUCTS

ALWAYS SATISFY YOUR NEEDS

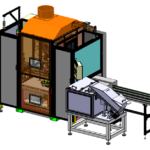

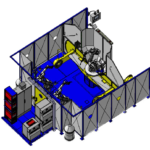

PLATEAU 4 POSTES

Featured product! (+100 in operation)

- Very high production flexibility.

- Modularity of processes (installation of studs - nuts - glue application).

- Checking of parts.

- Waste bin.

- Automatic unloading.

- Advanced Man/Machine interface.

- Compactness, simplicity.

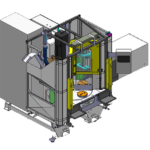

1 ROBOT CELL WITH 3 NUMERICAL AXES

View without extractor hood

- Very high production flexibility.

- Possibility to integrate many robot brands.

- Automatic tool recognition.

- Weight per station 1000 kg to 1500 kg.

- Gap from 2000 mm to 3500 mm.

- Tool diameter 1200 mm to 1400 mm.

- Advanced Man/Machine interface.

- Compactness, simplicity, mobility.

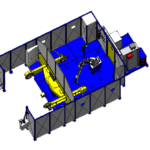

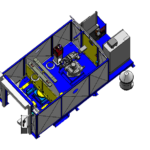

2 ROBOTS CELL WITH 3 NUMERICAL AXES

View without extractor hood

- Very high production flexibility.

- Possibility to integrate many robot brands.

- Automatic tool recognition.

- Weight per station 1000 kg.

- Gap of 3000 mm.

- Tool diameter 1200 mm.

- Advanced Man/Machine interface.

- Compactness, simplicity, mobility.

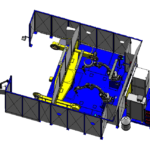

3 ROBOTS CELL WITH 3 NUMERICAL AXES

View without extractor hood

- Very high production flexibility.

- Possibility to integrate many robot brands.

- Automatic tool recognition.

- Weight per station 1000 kg.

- Gap of 3000 mm.

- Tool diameter 1200 mm.

- Advanced Man/Machine interface.

- Compactness, simplicity, mobility.

1 ROBOT LIGHT CELL

View without extractor hood

- Ideal for small and medium productions.

- Designed to adapt to the production flow.

- Possibility of integrating many robot brands.

- Automatic tool recognition.

- Weight per station 400 kg.

- Advanced Man/Machine interface.

- Compactness, simplicity.

PROCESSES

WELDING

This is the activity that made ACG's standing. Considered as experts, we master the different welding technologies.

ASSEMBLING

As the basis for all automation and added value of our resources, we master a large number of technologies.

HANDLING

From the transport of cotton swabs to the storage of boats, our solutions meet your quality requirements.

NEW PROCESSES

We guarantee you the best processes by mastering innovative technologies.