Project challenge

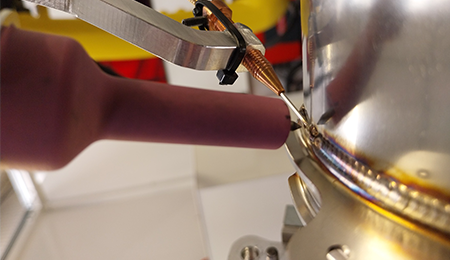

One of our customers in the sector wanted to automate the penetrant testing process on turbojet engine casings. This process, which is essential for detecting surface defects, previously required complex and time-consuming manual handling, increasing the risk of errors and inconsistencies in the treatment of parts.

Solution implemented

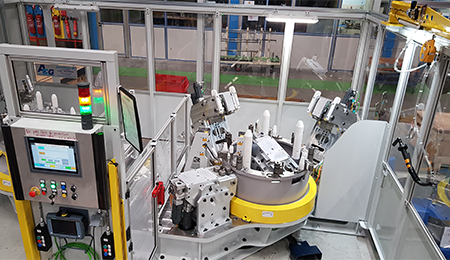

ACG has developed an automated penetrant testing line, incorporating :