Description

This cell incorporates two welding robots, enabling operations to be carried out in parallel or to complement each other. The 3-axis positioner ensures optimum placement of the parts to guarantee impeccable welding quality.

Main characteristics

- Two synchronised robots : faster production and reduced cycle times

- Digital positioners to optimise part orientation

- Ability to execute several welds simultaneously

- Intelligent interface for easy trajectory management

- Length between tips: from 2,000 to 3,500 mm

- Barrel size : 800 to 1,400 mm

- Weight per station : 500 to 1,500 kg

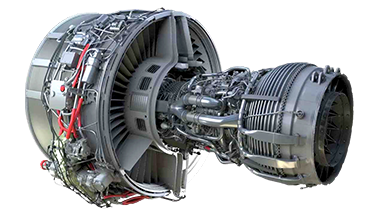

Applications

Simultaneous welding of large structure

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Large and medium series production in the automotive, aerospace and capital goods industries

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Optimisation of cycle times on multi-sided parts

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Derived applications

Gluing

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt.

Screwing

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt.

Crimping

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt.

Need customised support ?

Our experts can advise you on integrating the right robotic cell for your production !