Unrivalled performance

Our resistance welding platens are designed to deliver optimum performance and maximum precision when assembling metal parts. Robustness, reliability and safety are the key strengths of our solutions.

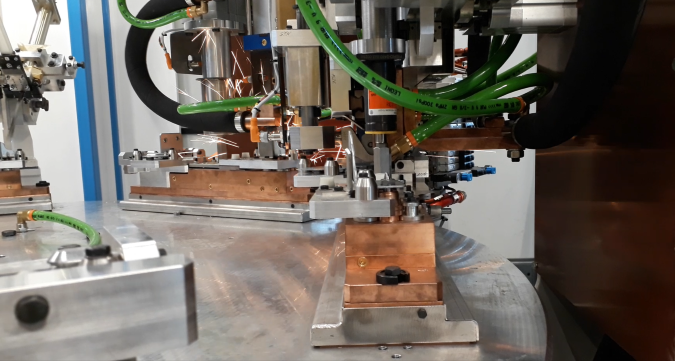

The welding platen holds the parts in place while guaranteeing uniform pressure and optimum distribution of the welding current.

Contact Us

Applications

The welding platen is ideal for the following applications:

- Assembly of metal parts

- Welding thin sheet metal without deformation

And for the capital goods and automotive sectors among others.

Our welding platens can be custom-designed to meet the precise specifications of your production line, guaranteeing a solution perfectly tailored to your requirements.

Platens designed for performance

Our welding platens incorporate the latest innovations in machine vision, simplified programming and man-machine collaboration, for unrivalled performance.

Explore our resistance welding platform

Technical details :

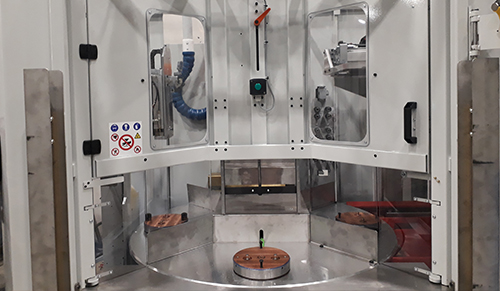

- Tray diameter : 820mm or 1200mm

- 4 stations

- Power : 250 kva

- Max. force 1.5 tonnes

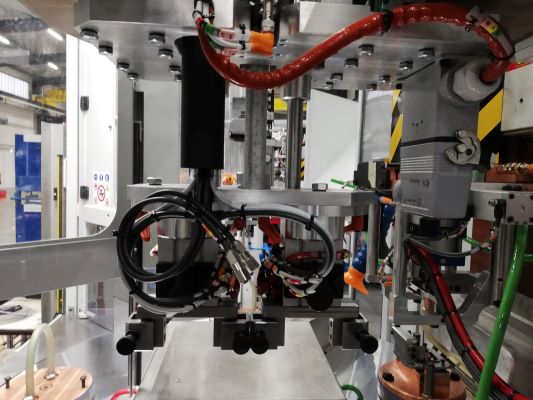

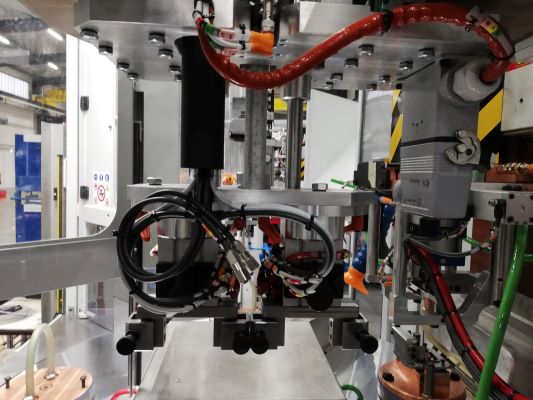

- Electric or pneumatic head

- Welding of 1 or 2 parts per turn of platen

- All-electric manipulator

- 4 possible welding cylinders

- 4 translations cylinders

- 2 other screw/nut orientations automatic or measurable nut/nut dispensing.

We can adapt our welding tables to your needs.

Ask our team for advice