Bin-picking is a central operation in many industrial processes. ACG Automatismes offers robotic uprooting solutions that combine advanced vision systems and intelligent algorithms.

Automated and infinitely repeatable, robotised uprooting processes take place in three stages. The first step is to acquire images of the bulk to be worked on. The second stage consists of processing the images and recognising the parts. Robotic handling is the final stage, tailored to your production system.

Contact Us

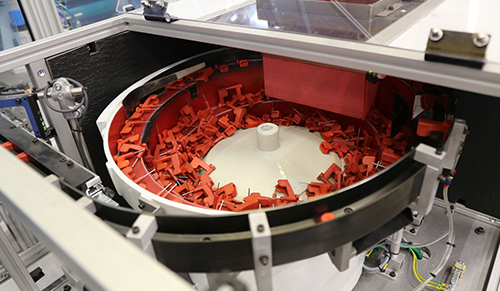

Our robotised bin-picking machines

Our customised robotic bin-picking machines are made up of multi-function articulated-arm robot manipulators, complemented by grippers adapted to the shape, size and material of the components to be handled. They are also equipped with 3D vision systems, image processing and part recognition software. A control and programming system – an advanced man-machine interface – enables each specific situation to be configured and managed.

Markets concerned by robotic bin-picking

Our made-to-measure bin-picking solutions drastically improve the productivity of many manufacturers.

The cosmetics sector also benefits from our solutions for sorting and organising bottles, tubes or bulk packaging with maximum speed and precision.

The automotive sector benefits from our systems for assembling small parts, combining high speeds and multi-format management to meet the specific requirements of this industry.

Consumer goods, such as spare parts, electronic components or hardware items, can be processed without human intervention without compromising their physical integrity.