Project challenge

Our customer needed to integrate a new manufacturing process with no existing solution for assembling nuts and components by electric welding on automotive parts. The challenge was to design an automated system that would guarantee precision, speed and versatility.

Solution implemented

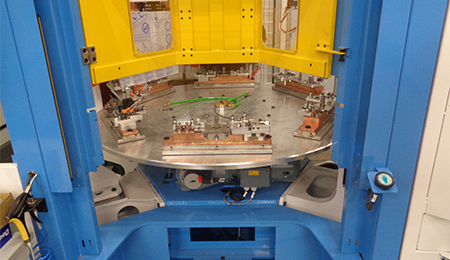

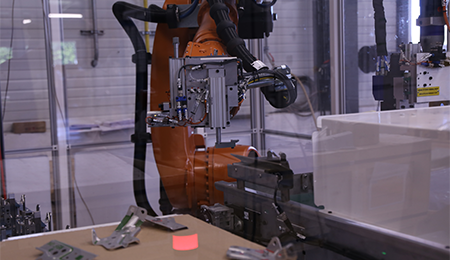

We have developed a 6-station welding table for continuous flow production. This multifunctional system assembles nuts and components using electric welding, while incorporating a final automatic packaging stage.

This solution improves productivity, while guaranteeing the repeatability and quality of the welds.