Robotic laser beam welding is a high-precision technology. It enables robust, aesthetic and repeatable assemblies to be produced on materials that are difficult to weld using traditional methods. The high-power concentrated beam ensures deep penetration while limiting deformation.

Suitable for light alloys and polymers, it is one of the best welding processes for assembling components with complex geometries. It guarantees splatter- and residue-free finishes, reducing the need for post-treatment.

Contact Us

Our robotised laser welding machines

We offer a wide range of solutions, from the 4-station welding table to the lightweight 1 robot cell. Each welding station comprises a laser source – CO2, fibre or YAG – integrated into a secure environment with a dedicated protected area. A beam focusing and guidance system ensures optimum process precision.

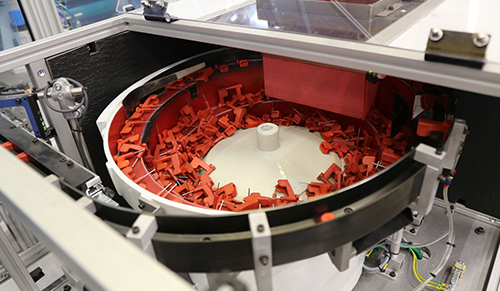

It consists of one or more robot manipulators with articulated arms that move the welding head. An automatic system positions the parts to be welded (turntable, conveyor), with tooling guaranteeing perfect docking of the components, to ensure uniform, high-quality welding.

In addition, we offer laser stripping solutions to optimise the preparation of surfaces before welding, thus ensuring the quality of assemblies and welds. Thanks to precise control of the process, our solutions limit post-treatments, reducing the number of finishing stages and improving overall productivity.

Each machine is controlled by an advanced man-machine interface, guaranteeing intuitive operation and precise control of the process.

The markets concerned

Our robotised laser beam welding machines are designed for manufacturers, SMEs and SMIs looking to improve their productivity and guarantee high added-value assembly. Thanks to its high precision and speed of execution, this technology is particularly well suited to sectors where the visual appearance of welds is an essential criterion.

The automotive industry uses it for aesthetic and robust welds, such as the assembly of bodywork roofs. The aerospace industry uses it for turbine blades and light alloy tanks. The consumer goods sector uses it for parts such as washing machine frames and hoover shells.

Widely used in cosmetics and pharmaceuticals, laser welding guarantees clean, reliable welds. It is also used in the arms industry for components with high mechanical requirements.