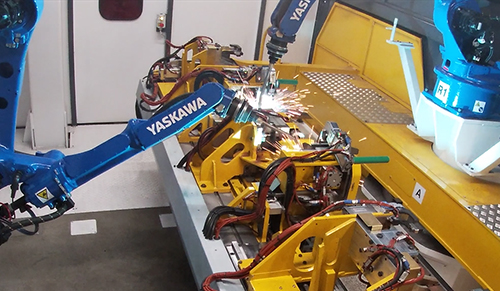

ACG’s robotised MIG/MAG welding is one of our various welding solutions. It uses a fusible electrode wire as filler metal. A gas to protect the molten metal from oxidation completes the system. The MIG process uses an inert gas, such as argon or helium. MAG technology uses an active gas, such as carbon dioxide or a mixture of argon and carbon dioxide. Automated MIG/MAG welding is versatile and can be used to weld a wide variety of metals.

Contact Us

Our robotised MIG/MAG welding equipment

Our MIG/MAG welding equipment incorporates solutions tailored to every need, from FlexiTurn Pro plates to Opti Flex cells for optimum performance, not forgetting the compact and versatile Opti Cell.

With advanced features such as automatic tool and part relocation and an advanced man-machine interface, our solutions offer maximum flexibility. We also offer multi-robot cells for increased productivity.

The markets concerned

Our robotised MIG/MAG welding machines meet the requirements of many sectors, including the automotive and capital goods industries. ACG has developed standard capacity solutions for the automotive and aerospace industries.

Thanks to the integration of vision and AI, our equipment adapts to the specific needs of each customer, optimising programming, trajectory tracking and welding efficiency. This flexibility also enables us to address a wide range of markets, from manufacturing to packaging, particularly in the cosmetics and pharmaceutical industries.

Innovative, customized welding solutions

We can help you bring your welding robotization projects to fruition