Are you looking for a solution to automate your welding operations ?

Automatismes CG offers you 40 years of expertise in customised design services for special machines. Thanks to our design office of 35 engineers and technicians, we can develop your automated welding solution, tailored to your needs.

Contact Us

Discover our different robotised welding technologies

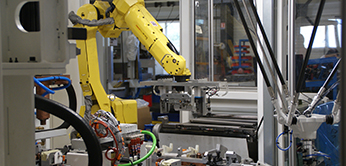

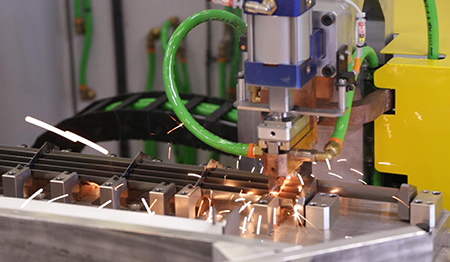

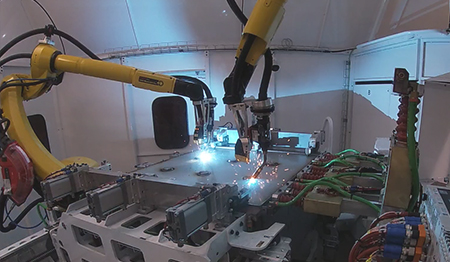

Thanks to our robotised welding solutions, we can help you produce at a high level of performance. Discover a wide range of robotic systems for resistance, TIG, MIG/MAG, plasma or laser welding. All our systems are designed to offer a high level of availability and flexibility to our customers, enabling several productions to be accommodated on the same machine. Our interfaces are highly focused on preventive maintenance and troubleshooting.

Automation and robotisation : the key to performance

Acquiring one of our welding robots guarantees optimum levels of precision, repeatability and speed, to enhance the performance of your manufacturing processes. Automating welding processes reduces production costs, drastically increases the quality of finished products and improves working conditions for your operators. ACG designs robotised welding cells that can incorporate robots from leading brands, top-of-the-range welding peripherals, vision systems and advanced man/machine interfaces.

Why choose Automatismes CG ?

Our process for producing your customised welding machine is fully integrated, guaranteed to be made in France and with no subcontracting. You can be sure that your project, monitored, managed and steered by a single contact, will be successfully completed, whatever your specific requirements and the complexity of your problem.

Thanks to our multi-sector activity, you benefit from the feedback of tested, validated and documented solutions, at the service of your project. We offer comprehensive support, from pre-project studies through to after-sales service, both in France and internationally. Our teams help users to develop their skills and ensure that they get the most out of their new tool.

Innovative, customized welding solutions

We can help you bring your welding robotization projects to fruition