Project challenge

The customer in this sector wanted to automate the crimping process. Performed manually, this operation could lead to variations in quality, significant physical effort for operators and long cycle times. The aim was therefore to make this process more reliable and automated in order to increase productivity and ensure consistent assembly quality.

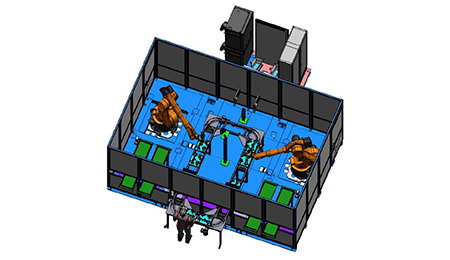

Solution implemented

ACG has developed an automated crimping line equipped with two robots and an advanced control system. Using precision tools and intelligent programming, the cell guarantees consistent, repeatable crimping, while optimising production time.